8 Pin Flat Ribbon Cable

- Description

- Contact Supplier Now!

Description

IDC 8 Pin Flat Ribbon Cable for Motherboard

The 8 pin flat ribbon cable has a good appearance, without defects of plastic injection molding, metal parts may not have scratches, deformation and other defects of performance to meet the requirements.

Specifications

| Cable | UL2651 28 AWG (7×36) stranded 300V |

| Cable Pitch | 0.05″ (1.27 mm) center spacing |

| Total Length | Custom |

| Color | Gray, black, yellow, or custom |

| Connector Type | 8 pin ribbon connector |

| Connector Row | 2 row |

| Pin Number | 8 pin |

| IDC Connector Pitch | 2.54mm pitch |

| Main Materials | Plastic |

| Rated Voltage | 300V |

| Conductor Resistance | MAX:237Ω/KM 20°C |

| Insulation Resistance | MIN:100M /KM 20°C |

| Temperature | -20°C~+105°C |

| Insulation Jacket | Eco-friendly PVC 45P(RoHS) 8058 grey |

| Service | OEM and ODM |

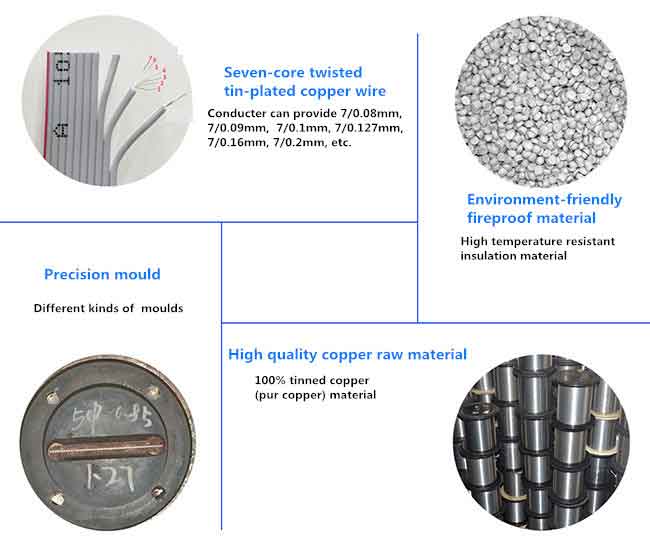

Production Process

Material selection – High-quality raw materials imported

ECOCABLES selects international 59-1 (special A grade) high quality brass, also known as musical instrument grade brass. High copper content, high hardness, less impurities, not easy to deform, smoother current signal transmission, lower signal loss rate.

Stamping – High speed stamping in one piece

ECOCABLES imports 18 large high-speed punching machines, stamping and forming the pins in one body to ensure product quality and screen out distorted, brittle and deformed products.

Electroplating – 5 layers electroplating process

In the full-length 120m automatic ring electroplating line, the surface of ECOCABLES products is electroplated in five layers to ensure that the products pass the 260/280-degree strict test | through 24-hour salt spray test.

Injection molding – Precision injection molding process

ECOCABLES has 30 molding line injection molding machines, using high-performance PET plastic raw materials imported from Taiwan to ensure the normal use of long-term high temperature conditions, excellent electrical insulation, and export standard injection molding process to ensure product life.

Assembly – pure manual assembly quality inspection

With more than 100 skilled workers, pure manual assembly of various accessories, and removal of defective products, the surface effect of the product control not only reflects the harsh technical standards but also reflects the belief in the pursuit of excellent quality.

Testing – Stringent quality inspection above international standards

Far higher than the international standards of strict testing procedures, quality inspection personnel one by one inspection, and through the salt spray test box, 280° high temperature test, do not let go of any defects.

Our Capacity

Custom Ribbon Cable Types:

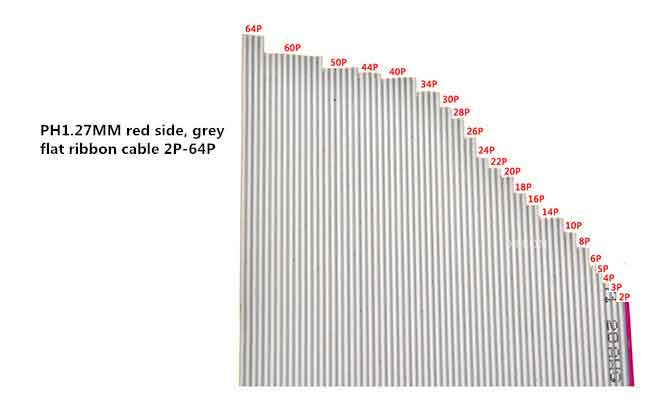

ROHS REACH cable

UL2651 28AWG 26AWG PH:1.27MM PH:1.0MM 3P 4P 5P 6P 7P 8P 9P 10P 11P 12P 13P 14P 15P 16P 18P 20P 24P 26P 30P 34P 37P 40P 50P 60P 64P

UL2678 30AWG Pitch:0.635MM 10P 12P 14P 16P 20P 24P 26P 30P 34P 40P 50P

Custom Ribbon Cable Connectors:

1.27*1.27IDC, 1.27*2.54IDC, 2.0IDC, 2.54IDC DIP, CE, butterfly buckle, bull horn… …

How to Order

1. Talk to us about your ribbon cable – 2. You (or our engineer) provide drawing – 3. Confirm drawing – 4. Quote – 5. Sample built – 6. Sample approved – 7. Payment – 8. Mass production – 9. Test before shipment – 10. Delivery